GoPlant Industries

The Right Solution for a Range of Industries

No matter your industry, GoPlant is an operator tool that efficiently gets critical data to the right people for real-time decision making. GoPlant helps optimize performance and continually improve safety, operations, reliability and regulatory compliance. Bottom line, digital leaders find GoPlant to be an effective tool to support business goals.

Explore solutions by industry.

Oil, Gas & Chemical

GoPlant enables process industry facilities to eliminate paper operator rounds, checklists and inspection forms by using rugged and/or intrinsically safe tablets instead. GoPlant includes decision support features that can enforce SOPs when starting up, shutting down and checking running equipment. Operators can enter readings and access weeks of past data at each stop on their operator rounds. Managers can view detailed charts, reports and alerts. All without transcription.

Features

- Automate operator rounds with flexible scheduling frequencies

- Environmental, health and safety inspections

- Asset failures and safety issues caught mitigate risk, damage, and costs

- Allows for barcode, NFC tag or QR code to be assigned to specific assets

- Define roles and assign users specific access to desktop/web application

Pulp & Paper

Operating costs for pulp and paper production are always an area of focus for management. GoPlant plays an important role in finding the next level of cost optimization, arming frontline operators with technology to impact machine efficiency and availability while reducing costs. In addition to machine monitoring, your staff can perform visual inspections guided by instructions and record information such as pressure, flows, lubrication levels and more. The data collected can also be used to automate support for activities such as plant safety, EHS audits and environmental and quality inspections.

Features

- Easy to get started and easy to use with guided measurement support

- On-the-spot machine diagnostics with color-coded visual alarm indicators

- Store, share and report on data collected

- Customize forms for inspection and process data collection

- Allows for barcode, NFC tag or QR code to be assigned to specific assets

- Asset failures and safety issues caught early mitigate risk, damage, and costs

Mining, Aggregates & Cement

In these industries, harsh environments are being dealt with daily. That’s why it’s critical to know when assets could start to have potential issues. GoPlant enables operators, maintenance and reliability teams to have access to all critical information needed to keep their sites running smoothly. Management teams can take action and address immediate issues as soon as readings are taken with email alert alarms. Utilizing GoPlant will help move you toward a proactive maintenance approach and can reduce unplanned downtime.

Features

- Instant access to vibration and temperature readings with trending capabilities

- Step-by-step instruction to ensure proper procedures are always followed

- Shared access of all critical information between cross-functional teams as necessary

- Utilize task creation to ensure inspections are done in a timely manner

- Ability to work offline when data is unavailable

- Equipment conditions can change quickly – early identification and repair can save significant costs and improve safety

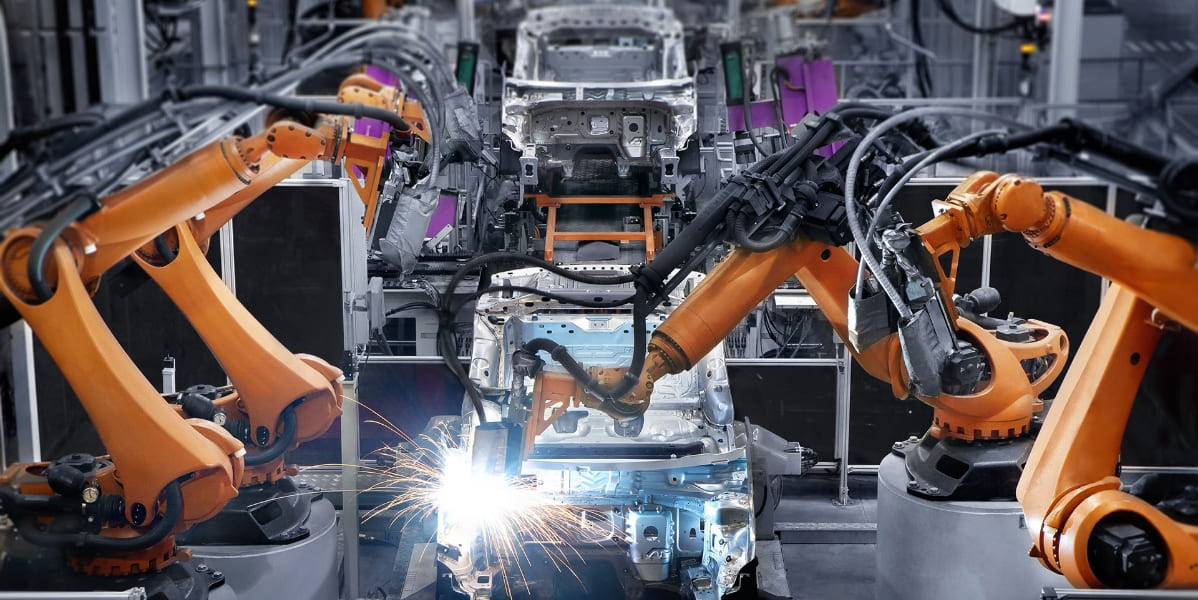

Metals

Few industries can match the extreme operating conditions in steel and other metal mills. GoPlant can help you stay ahead and adapt – and even increase quality, reliability, improve worker safety and uptime – when the demands for output keep getting higher. Operator data helps you make informed decisions to optimize production, create, schedule and execute maintenance best practices and minimize downtime. As a complement to your maintenance program, you can equip operators with the SKF QuickCollect sensor and send them preprogrammed vibration inspection routes to guide their activities.

Features

- Confirmation maintenance checks are completed with name, date and time stamping, enabling quick decisions

- Easily document visual inspections and vibration levels and escalate issues via email alerts

- Ensure best practices are followed and support proactive maintenance strategies

- Equipment conditions can change quickly – early identification and repair can save significant costs and improve safety

- Easy to get started and easy to use with guided measurement support

- On-the-spot machine diagnostics with color-coded visual alarm indicators

Power Generation

GoPlant leads your operators through their rounds checklist and other tasks and enforces your standard corrective action and escalation procedures when unusual field conditions are discovered. Insightful reports and charts are available from any WAN-connected desktop browser, and email/text message alerts are issued upon triggering events in the field. GoPlant server can serve a single facility or scale up to serve multiple plants in a generation fleet.

Features

- Enforce timely and complete operator rounds

- Perform environmental, health and safety inspections

- Equipment start-up and shutdown procedural checklists

- Ability to perform rounds offline and snyc data when WiFi is restored

- Display past readings to operators while in the field

Water/Wastewater

GoPlant allows water and wastewater plant operators gather rounds data, water quality measurements and other non-instrumented data collection without paper and pen. Readings, comments, photos of specific assets can all be gathered with or without a network connection. Start-up, shutdown and running equipment checks can be enforced the same way, every time, ensuring a smooth operating facility.

Features

- Enforce timely and complete operator rounds

- Ensure start-up, shutdown and other procedures are done correctly

- Water quality data collection

- Environmental, health and safety inspections

- Capture valuable operator knowledge to share with upcoming digital generation

- Digitize repetitive tasks and empower frontline operators

General Manufacturing

Manufacturing operations require regular start-ups, shutdowns and center-lining of manufacturing equipment. The paper forms used to document these checks quickly pile up and become forgotten. Trends and issues discovered in these checks, if seen over time, can make the difference between a smooth manufacturing run and piles of wasted product.

Features

- Equipment start-up, shutdown and center-lining checklists

- Product quality inspections

- Easily configure and align GoPlant to your specific business requirements

- Use smart inspection forms to ensure product specifications are met

- Store collected data to take informed action and reduce downtime

Food & Beverage

GoPlant provides food and beverage processors with a powerful tool for improving food safety, product quality and traceability data collection efforts, all while eliminating paper from the plant floor. Collected data is stored in the powerful GoPlant database, permitting rapid, secure sign-off, actionable charts and reports and confidence that data was collected when, where and how it should be.

Features

- HACCP and food safety audits

- Product quality and attribute data collection

- Ingredient traceability

- Pre-shipment and document reviews

- Pest control inspections

- Comply with FDA, USDA and other regulations and guidelines

- Lower product and packaging waste

|